What Air Movement Provides The Best Drying Environment – Dynamic Air

Dynamic Air Movement in paint booths has efficiently improved the drying times of wet paint on vehicles or parts. There are several different air movement methods used in drying systems; including directed air, turbulent air, and the newest dynamic air movement. The biggest obstacle in paint drying with air movement systems is breaking the boundary layer.

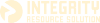

The boundary layer on vehicles or parts is a difficult barrier to overcome in paint drying processes and causes drying times to increase drastically if not effectively broken. The boundary layer is a layer of stationary vapor (water or solvent) surrounding an object when air is moving around the object. The boundary layer, depending on how the air is aimed, is usually small at first contact, but as the air continues to move along the surface the boundary layer increases. If there is an obstruction, like door handles, bumper grills, and fog lights, the layer will extend significantly making it more difficult to dry.

- In an attempt to break the boundary layer, Directed Air Movement systems can be used and powered by air compressors, blower motors, or fans and use:

- Booth Mounted Towers with Directed Nozzles

- Handheld Venturi

- Tree with 2-3 Handheld Venturi

|

|

|

|

|

|

The user must handle and aim the systems at strategic obstruction spots like mirrors, door handles, etc. in order to dry. The issue with directed air-drying systems is the high velocity air movement used to break the boundary layer results in overspray debris being stirred in the paint booth thus contaminating the paint job. The boundary layer is only broken directly where the nozzle is pointed and is unable to penetrate all surfaces and has difficulty drying grooved surfaces like bumpers.

- Another method of breaking the boundary layer uses Fixed Turbulent Air:

- Air Knives

- Air Knives with Deflectors

- Propeller Fans

|

|

|

The units are mounted in a specific manner for fixed air movement to occur. In some cases this air moves in a whirlwind creating a tornadic effect. These circular air movements mimic the air movement seen in tornadoes, resulting in the center of the “tornado” not receiving equal air movement. This pattern of air movement is notorious for picking up and spreading overspray debris due to its higher velocity and pressure.

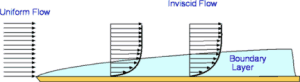

- The newest technology, Dynamic Air Movement, is used to vastly improve the drying speeds by making the booth environment into a drying chamber. The steady pressure as well as inconsistent velocity air movement creates an ideal drying environment for the most difficult places like bumper grills and fog light areas. The multidirectional movement of the air, created by working with the existing air movement, cross draft, down draft, or semi-down draft, allows for the penetration of the boundary layer and effectively dries every surface of the vehicle, including the hard to dry surfaces like bumpers.

Dynamic air movement’s ability to break the boundary layer is important in the drying process. The boundary layer is a layer of vapor that creates a barrier trapping the remaining solvents in the paint. If a drying system is unable to break the boundary layer the process time is extended and if moved on to the next application too quickly the paint job could be ruined, either requiring a redo or will not last as long. Dynamic air moves the vapor, dries in a consistent fashion, and results in the reduction of process time.

Contamination is another issue that occurs in air movement systems. High velocity systems are notorious for stirring debris in the paint booths and contaminating paint jobs. Dynamic air’s use of low velocity air movement eliminates contamination, whether that is stirring overspray, lifting the protective paper or plastic on vehicles, or moving debris that has been left in the paint booth.

The number one obstacle in successfully drying cars in an efficient manner is the unit’s ability to break the boundary layer at all surfaces, including the most difficult. Dynamic air systems have been found to have the best results in successfully breaking the boundary layer and drying wet surfaces more effectively and efficiently than other types of air movement systems.

Keys Factors to Air Drying Paint Effectively and Efficiently

https://beccainc.com/6769-2/