In our travels, we have found that 8 out of 10 painters claim they do not have effective drying systems. We hear painters say, “The air drying system is terrible…. I don’t use it!” Painters are unhappy unsatisfied waterborne drying system!

|

What Painters Have: |

What Painters Need: |

|

|

|

What Owners Have: |

What Owners Need: |

|

|

Air Movement systems can have drastic influences on an auto body repair shops profitability in several ways.

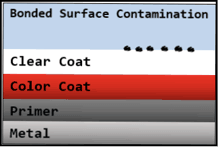

- Contamination

- Slow Dry Times

- Operating Cost

- Initial Cost

These issues occur in many air movement systems in the auto body repair industry. Due to old research, many air movement systems fail to provide quality drying capabilities shop owners and painters desire to see.

- High velocity systems creating lift of overspray from the floor and walls.

- Moving fan blades inside the booth, generating a static charge, collecting overspray, and releasing when started

- Over spray collection on nozzles, released when turned on

- Lack of maintenance on mechanical systems causing vibration displacing overspray

- Leads to additional processes of redo’s or reworking (nib and buff)

- Operator moving systems continually inside and outside of the booth

- Not Using System due to contamination

- Missed areas because of dead spots in air movement

- High velocity air across surfaces can trap vapor in grooved surfaces; such as bumpers, door handles

- Improperly cleaned spray guns resulting in heavy film builds requiring longer dry cycles

- Movement of trees or handhelds to need areas.

- Design for painter to change direction of nozzles not occurring

- System does not provide ideal air movement to accelerate drying in all surface

To read more on this issue refer to article: What Air Movement Provides the Best Drying Environment – Dynamic Air

Operating Cost

- Use of compressed air – most expensive utility in body shops

- Cost of moving parts around

- Cost of redo’s and rework (nib and buffing)

- Slow dry times

To read more on this issue refer to article: Electric High Static Blower versus Compressed Air

To read more on this issue refer to article: Electric High Static Blower versus Compressed Air

Initial Cost

- Expensive – $10,000-$30,000

- Issues Created

- Not Being Used

- Feeling Trapped with a System

These issues affect the profitability of the paint shop. The initial cost and cost of operation can result in wasted cash. Long dry times prevent higher turnover rates of painted vehicles and contamination, requiring extra steps to provide quality to the customer. In many shops, these issues can absorb a lot of time and money and affect shop efficiency. Utilizing proper air movement systems can help your painter finish more vehicles with less contamination and the save auto body repair shops money. Creating this higher efficiency reduces average rental days for insurance companies… making your shop more appealing for additional work!

Keys Factors to Air Drying Paint Effectively and Efficiently