Re-do’s, Repairs, Heavy Films, and/or Nib and Buffing can all be signs of a deeper issue occurring in paint shops. All of these processes are wasted time, eating away from a paint shops profit and ability to create an efficient operation. As it relates to spray guns, re-do’s and repairs occur as a result of tiger stripping or uneven paint application. Heavy film builds can take excessive time to dry and nib and buffing occur as a result of contamination. The cause is dirty paint spray guns. Dirty spray guns cost shop profits.

Re-do’s, Repairs, Heavy Films, and/or Nib and Buffing can all be signs of a deeper issue occurring in paint shops. All of these processes are wasted time, eating away from a paint shops profit and ability to create an efficient operation. As it relates to spray guns, re-do’s and repairs occur as a result of tiger stripping or uneven paint application. Heavy film builds can take excessive time to dry and nib and buffing occur as a result of contamination. The cause is dirty paint spray guns. Dirty spray guns cost shop profits.

Many painters do not take the time to properly clean spray guns, in many cases due to the lack of a cleaning process, proper cleaning equipment, or not knowing how to properly clean the spray gun. Most spray gun cleaners can make the cleaning process a hassle and worsen the spraying condition of the spray gun. Therefore, many painters do not use some spray gun cleaners and return to cleaning the guns by hand. Both being inefficient for paint shops. The hand-cleaning process may give the painter more control, but knowledge of the cleaning process results in missed areas, let alone the added time for each cleaning process.

Why do spray guns malfunction when not cleaned properly?

Why do spray guns malfunction when not cleaned properly?

Coagulated paint on internal components of the spray gun cause spray guns to malfunction. Coagulation occurs when paint dries internally on the spray gun, collecting in the air passageways or fluid passageways of the spray gun. As the gun is continually used, more paint residue sticks to the dried paint, creating a larger surface with dried paint buildup.

Paint buildup disrupts the air and fluid flow in the spray gun, disrupting proper atomization and causing an uneven spray, the size of the spray pattern to shrink, or spits. The result is tiger stripping, heavy films, or contamination on the painted surface, the reason why re-do’s, repairs and long dry times occur. All of which can be prevented. Air atomization determines droplet size and pattern size affecting film build, tiger stripping, and/or modeling.

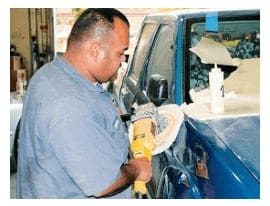

Properly cleaned spray guns not only improve the quality of the paint job but increase the productivity in the shop, meaning higher profit margins. Thus, more paint jobs get finished, less paint wasted, and shop profits increase. Knowing how to properly clean spray guns and having the appropriate equipment to clean spray guns can drastically improve shop efficiency and reduce wasted time and money.

Do You Have These Issues? Heavy Paint Application, Tiger Stripping, Long Dry Times, and/or Modeling