Challenges To Drying Solvent And Waterborne Paint

As a result of paint being applied in a liquid state there is an ongoing challenge to reduce the time to transform to a solid state or in other words “Dry”. In order to accelerate this process there have been many techniques used. For example, you will hear terms like drying, hardening, and curing. First we need to clarify each of these terms.

- Drying – The paint drying process evaporates all solvents and diluents used in the paint to make it liquid or reduce its viscosity.

- Hardening – the hardening of paint when the main polymer of the paint hardens with all other pigments and additives creating a solid coating.

- Curing – The paint curing process includes both drying and hardening process. Curing = Drying + Hardening

Paints can be classified by their curing mechanism. This includes:

- Chemically curing paints – Chemical curing paints represent where the main resin (polymer) is created through chemical reactions (poly reactions) between various compounds, in this type of cure includes both drying and hardening process. Examples: Polyurethane, epoxy, phenolic resins and polysiloxanes.

- Physical curing paints – Physically curing paint occurs when the main resin is already formed, therefore, to cure the paint requires evaporation of the solvent is required. Examples: Nitrocellulose lacquers, acrylic lacquers, chlorinated rubber paints and vinyl paints

All physical or chemical cured paints can accelerate or activate the curing process by applying one of the following techniques:

-

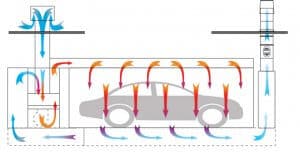

- Air – Using ambient air movement to remove solvent vapor allowing for solvents to continue to move out of the paint materials.

- Heated Air – Using heated air at a certain temperature accelerates the evaporation of solvents and accelerates the chemical reaction to the main polymer or resin, for instance the temperature acts as a catalyst which accelerates the drying and hardening process, thereby accelerating the curing process.

- Oven – Hot air recirculating is the most common method to accelerate the curing process regardless of the parts geometry.

- Radiation – Radiation curing or infrared technology for increasing the substrate temperature accelerates the paint curing process. Ultraviolet radiation technology activates the chemical reactions, as a result the paint cures.

The main advantage of the radiation curing is the speed to solidify the paint, achieving curing times in order of seconds, as disadvantage this type of curing only can be applied in areas where radiation emitted can see all surfaces, therefore it is typically not used in complex workpieces with different shapes and hidden areas.

Let’s take a look at each from a comparative analysis:

Types of Drying Systems

| Performance Parameters | Ambient Air | Hot Air | Hot Air w/ Directional Assist | Infared-Short Wave* | Infared-Gas Catalytic |

| Speed | 3 | 5 | 8 | 10 | 10 |

| Accuracy | 6 | 7 | 10 | 5 | 6 |

| Capital Cost | 10 | 8 | 7 | 5 | 3 |

| Operating Cost | 10 | 7 | 8 | 6 | 9 |

Performance Scale is 1 (Low) – 10 (High) * Cures what is exposed to radiant waves

In each case, the technology selected has a goal of reducing the drying time of the painted object in order to increase the productive capacity of the operation. The key is to select the correct technology, the best value for an operation to be successful.

Please visit our KnowledgeHUB for more articles:

Our FLASH DRY with ![]() can save 20-50% on drying times using our proven technology using dynamic air movement, directional air control, dehydrating, and dries faster then any other technology.

can save 20-50% on drying times using our proven technology using dynamic air movement, directional air control, dehydrating, and dries faster then any other technology.