“Spray Gun Performance”

The BECCA Investigation

Spray guns functionality in paint shops is critical for maintaining quality finishes on paint jobs. At BECCA, we have found issues regarding the performance and maintenance of spray guns. We approached this challenge by acquiring spray guns used in the field, then studied various issues found. Next to assessing how to prevent each from occurring. We cut each gun in half, which enabled us to observe the build-up of paint materials, wear and tear on internal components. From this analysis, we began building a process around protecting the areas of concern.

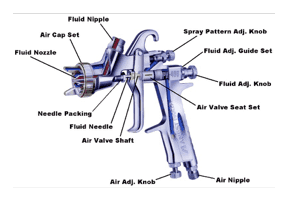

Those areas of concern consist of…

Major Performance Areas

Major Performance Areas

- Fluid Tip

- Needle

- Fluid Needle Packing

- Air Cap

- Air Distribution plate (some paint guns)

- Air Passageways

- Minor Areas

- Spray Gun Body

- Trigger

The biggest issue in cleaning spray guns is the lack of appropriate tools to make cleaning for the painter easy. Therefore, at BECCA we have designed our gun cleaners to make cleaning the gun easier, more effective, and much quicker than previous methods. When proper cleaning does not occur the following areas are affected…

|

Fluid Tip: Blockages or paint buildups will prevent the proper flow of fluid and disrupt the volume of paint supplied |

|

Needle: Paint buildup on the needle can cause trigger sticking and disrupt or reduced fluid flow, affecting your spray gun’s ability to spray effectively. |

| Fluid Needle Packing: Paint buildup on the needle, particularly with waterborne because the dry material acts like sandpaper against the packing surface, ruining the packing and leading to leakage | |

| Air Cap: Build-up and blockages in the air cap will prevent proper airflow, resulting in disrupted spray pattern, causing paint defects such as tiger stripping, mottling, or other paint-related issues. | |

| Air Distribution Plate: Build-up and blockages on the Air Distribution Plate will prevent proper airflow, disrupting the spray pattern, causing paint defects such as tiger stripping, mottling, or other paint-related issues. | |

| Air Passageways: paint will work its way into the air passageways affecting airflow through the spray gun. With waterborne materials on internal components of the spray gun eventually will cause corrosion. |