Re-do’s, Repairs, and/or Nib and Buffing?

|

|

BECCA has developed a series of tools that make up the 3P System. These tools are for the spray gun cleaning process based on the testing and feedback of top painters from all over the country. These tools have been developed to achieve maximum success with very little effort in a short period of time. BECCA has developed a series of tools that make up the 3P System. These tools are for the spray gun cleaning process based on the testing and feedback of top painters from all over the country. These tools have been developed to achieve maximum success with very little effort in a short period of time. |

| As the 3P System is being introduced across the country shops are experiencing results, thus saying yes to the 3P System. This system works with waterborne as well as solvent paint keeping spray guns in like new condition. What does this mean to you? Less paint waste, high quality jobs, meaning less time dealing with Re-do’s, Repairs, and/or Nib and Buffing. |

|

Here is our team has found and implemented into the 3P System

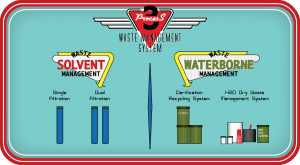

Spray guns used with solvent based materials can primarily be cleaned with solvent. Waterborne materials are far more difficult to clean and unfortunately. The standard process of chasing with solvent (usually acetone) creates more issues than it solves. Solvent mixed with waterborne paint causes waterborne paint to become and behave like a solvent paint. The remaining paint in or on the spray gun will create a strong adhesion to the surface, eventually causing performance problems or corrosion. Spray guns used with solvent based materials can primarily be cleaned with solvent. Waterborne materials are far more difficult to clean and unfortunately. The standard process of chasing with solvent (usually acetone) creates more issues than it solves. Solvent mixed with waterborne paint causes waterborne paint to become and behave like a solvent paint. The remaining paint in or on the spray gun will create a strong adhesion to the surface, eventually causing performance problems or corrosion. |

| [more information] |

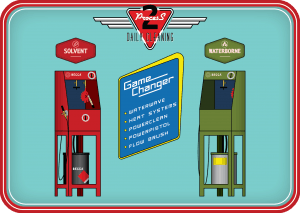

| The BECCA 3P System takes Spray Gun Cleaning to the ultimate level: |

High Level Of Cleaning High Level Of CleaningIf all steps of the process are followed then the gun will be like new all the time

|

Very Low Cost To Operate Very Low Cost To OperateLow Maintenance costs

Only uses a small amount of compressed air

|

|

Hazardous waste – Regular Waste

|

|

Understanding The BECCA 3P System [view here]

Does Your Shop Spend too Much on Re-do’s, Repairs, and/or Nib and Buffing? [read more]

|